All Categories

Featured

Table of Contents

- – Rv Dining Table Orange, CA

- – OCRV Center

- – Replacement Rv Refrigerator Orange, CA

- – Rv Sofas Orange, CA

- – Rv Interior Furniture Orange, CA

- – Replacement Rv Windows Orange, CA

- – Awnings For Rv Orange, CA

- – Rv Sofa Beds Orange, CA

- – Replace Rv Flooring Orange, CA

- – Rv Replacement Furniture Orange, CA

- – Rv Couch Bed Orange, CA

- – Awnings For Rv Orange, CA

- – OCRV Center

Rv Dining Table Orange, CA

Similar to the windows in your automobile or home, there are a few different kinds. Perhaps you want a window in your door to ensure that you can allow the sunlight? Examine! The Recreational Vehicle Entry Door Obscure Glass Home window is ideal for that, with the addition that you can have your privacy while still allowing the light.

And if you desire your home windows to be tinted, we can help you there. I'm sure you're mindful of all that a window can do.

Without the home windows to allow in the light to inform you whether it's evening or day, you could get all sort of blended, perhaps even miss a big event. Or imagine you're having a picnic with your household and you run inside to get some even more hot pets. Without a window, you wouldn't have the ability to see that your little girl is obtaining very near to the fire and no person else has observed yet.

Replacement Rv Refrigerator Orange, CA

The sunlight is a wonderful decorating device to utilize, illuminating area and visually increasing it. All the very best designers recognize exactly how much of an impact lighting can have. Whether you're utilizing it to accentuate an outstanding item of artwork or add heat to a whole room, illumination makes all the difference in an area.

If you have older home windows that require changing, the procedure for installing the brand-new home windows isn't as easy as it looks. You require to eliminate the internal framework of the old window by removing the screws. You need to get rid of the external frame of the window by pushing it out of the window location.

Next, get rid of any one of the old sealants from the location with a putty blade. As soon as that is done, clean the location with an appropriate cleanser. When your location is tidy and free of debris, examine the structural components of the window opening. If there is anything that needs taken care of (rusted staples, for instance), see to it you repair them before mounting the new home window.

Again, make certain you are using the assistance of an additional person to maintain every little thing straight and also and prevent the home window from falling. When the external frame and the glass framework are in area, secure them by placing and protecting the inner frame on the within of the window location.

Rv Sofas Orange, CA

Our company believe in providing the best worth, top quality, and choice (Rv Interior Remodel Orange). Plus, we want you to enjoy your purchase! In case you want to send an item back to us, you may return most extra things for a reimbursement or exchange, minus shipping, within 90 days from the day of purchase unless noted listed below under exceptions and exemptions

For web orders, please contact our customer care team(1-888-626-7576) to ensure your return or exchange is documented and any potential questions have been answered. In many cases, a return authorization will certainly be supplied, and, in every situation, we'll begin to watch out for your return. For web orders returned in-store, please take the thing in initial packaging, together with the invoice to any type of Outdoor camping World retail areas for a reimbursement or exchange.

Rv Interior Furniture Orange, CA

Refunds for internet orders issued in-store are able to be reimbursed to a GIFT CARD or MAILED CHECK ONLY; some exclusions might use. For retail acquisitions returned with a receipt, please return the extra and unopened thing, with the initial sales receipt, for a complete reimbursement or exchange. All returns with a present receipt will certainly receive an installment plan for the amount of the thing at the time of acquisition.

When it comes to Motor home traveling, having the right home windows can make all the distinction. Whether you're looking for far better insulation, improved ventilation, or simply a much better sight, there are a few vital elements to think about when selecting the best RV window for your car. Here are 5 suggestions to aid you make an educated decision and appreciate your trips to the maximum.

Replacement Rv Windows Orange, CA

Fixed home windows are stationary and can not be opened, while gliding home windows can be opened flat or vertically. Awning windows are pivoted on top and open outside, offering excellent ventilation. Take into consideration the kind of window that will best suit your requirements and preferences before purchasing. When choosing a motor home window, it is very important to look for top notch products and building and construction.

Look for windows that are made from solidified glass, which is stronger and extra immune to breakage than normal glass. In addition, the structure must be made from sturdy materials like light weight aluminum or plastic, and should be designed to prevent leakages and drafts. Purchasing a top notch recreational vehicle home window will certainly make certain that it lasts for years and gives reliable performance on your trips.

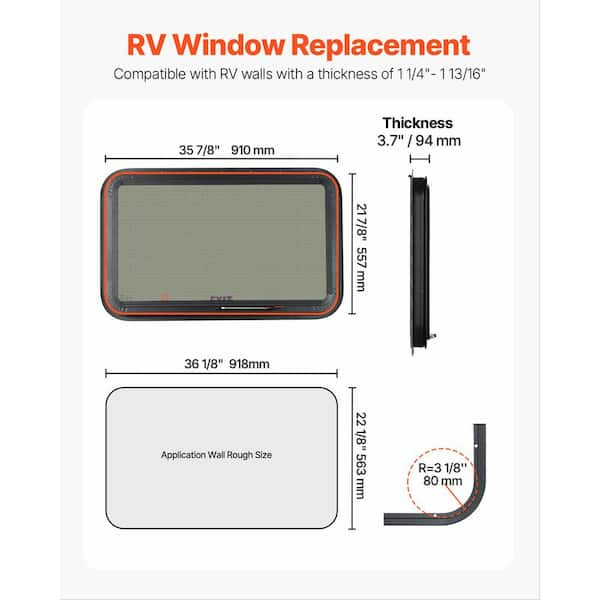

The window should fit well right into the room provided, with no spaces or areas that can enable drafts or leakages. Procedure the opening very carefully and pick a home window that matches the dimensions. Additionally, take into consideration the form of the window and how it will fit with the general layout of your recreational vehicle.

Awnings For Rv Orange, CA

Your recreational vehicle's windows are the key to satisfying camping, letting you see all the views of the road and your locations. If you're driving a motorhome, the windscreen is one of the most crucial window on the entire recreational vehicle. Despite which sort of RV you have, your home windows are a fundamental part of outdoor camping.

Older Recreational vehicles were built with much less sophisticated window systems, so there is wear and tear that may appear. Not to stress, you can see things plainly once again by replacing your motor home windows! Some recreational vehicle window issues might be solved when you deep clean your RV, however certain issues like haze, scratches, or concerns with the covering of the window might mean it's time to replace your recreational vehicle home windows.

There are fractures, deep scratches, or contribute the home windows. The home windows are no more firmly secured. Wind or water gets in the gear from around the home windows, also when the home windows are shut. Your home windows aren't correctly insulated. Your windows rattle when the RV is in activity. Wondering if it's time for a RV home window replacement? Contact your neighborhood Lazydays motor home dealer to read more concerning our window replacement and motor home glass repair service solutions! When replacing your recreational vehicle home windows, you have the ability to choose the right window for your motor home and your needs.

Rv Sofa Beds Orange, CA

There are also options such as clear glass, pebbled windows, and tinted RV home windows. Your design, safety and security, and window make use of demands will certainly aid determine which sort of RV home window you pick. Your RV's home window structures incorporate the exterior and interior elements of your recreational vehicle, and they ought to be correctly installed to make certain that the sidewall's seal continues to be leak-proof.

The most effective method to make sure that your recreational vehicle home window substitutes are set up correctly is to leave it to the experts. Our recreational vehicle solution specialists can replace any kind of home windows and glass on your motor home, including the windshield, side home windows, and even the more complicated motor home door home window replacement. Door home windows, if not mounted effectively, can rattle when you're making use of the recreational vehicle door, so leave that repair to our professionals at Lazydays RV.

Replace Rv Flooring Orange, CA

These home windows open outward with a crank mechanism, enabling for ventilation while reducing rainfall access (Rv Interior Remodel Orange). Often bigger windows that do not open, giving unobstructed views and light if geared up. Prior to we study the procedure of RV home windows, it's necessary to comprehend just how they are mounted. Below's a short introduction of the parts associated with a common home window installation: The main glass unit.

Fasteners safeguarding the keeping ring. Offers a leak-proof seal around the window. These parts are mounted on the assembly line shortly after the wall surface assembly, making sure the architectural stability of your motor home. While RV windows differ from household windows, they call for routine interest and maintenance to avoid problems like water leaks.

Rv Replacement Furniture Orange, CA

To ensure the durability and efficiency of your RV windows, consider the complying with pointers: Check out the location where the window satisfies the wall surface for any gaps or gaps. In severe cases, you might require to get rid of the window and re-install it making use of putty or foam seal.

We urge customers to verify the components and talk to their dealership or Keystone motor home for the most present information. If you have any kind of questions or require more information, please do not be reluctant to contact your dealership or get to out to Keystone motor home directly.

These are the devices we required for our camper home window replacement. Depending on your Motor home, you may or might not require all of these tools for your project.

No matter where you acquire your new Recreational vehicle window, you'll require to supply accurate dimensions. Let's break down our procedure for gauging a RV window for replacement.

Rv Couch Bed Orange, CA

Do not place any exterior stress on the window while taking your dimensions, or it could come loosened and autumn. For additional safety, you may want to have a helper on a ladder outside, holding the home window in area while you determine. Meticulously get rid of the framework of your old home window to ensure that you can gauge the opening (NOT the home window itself).

For our rectangular window, we required to take just 4 measurements. It's a great concept to take measurements at numerous factors so you have a concept of how easily the home window opening was reduced.

Awnings For Rv Orange, CA

Next, gauge the thickness of the wall (deepness of the window), from the outside wall surface area to the interior wall surface. For this measurement, use your ruler (with measurements that run right throughout). Put the ruler into the wall surface up until it touches the outside of the window framework.

Dimensions of the old window and the home window opening are usually different. Home window producers utilize filler strips to keep the home window level and snug.

Action twice, cut when? Take your time to get a precise dimension, and verify it by determining a second time. Specific measurements are very important to RV home window replacement. You do not desire to freely measure and round up or down. Constantly gauge to the nearby 1/16th of an inch. Take a close check out your measuring tape and be certain you understand which are the 1/16th-inch measurements.

OCRV Center

Address: 23281 La Palma Ave Yorba Linda, CA 92887Phone: (714) 909-1444

Email: [email protected]

OCRV Center

The window producers are the best authorities on mounting their items. The producer of your new Motor home home window has likely consisted of useful standards or pointers to make the installment easier.

Replacement Rv Windows Orange, CAReplacement Windows For Campers Orange, CA

Rv Sofas Orange, CA

Rv Couch Orange, CA

Rv Interior Furniture Orange, CA

Rv Refrigerator Replacement Orange, CA

Rv Carpet Installation Orange, CA

Awning Installation Orange, CA

Rv Replacement Awnings Orange, CA

Replace Rv Flooring Orange, CA

Rv Carpet Replacement Orange, CA

Replacement Windows For Rv Orange, CA

Rv Interior Furniture Orange, CA

Replacement Rv Refrigerator Orange, CA

Replacement Windows For Campers Orange, CA

Rv Replacement Awnings Orange, CA

Replacement Windows For Rv Orange, CA

Rv Refrigerator Replacement Orange, CA

Replacement Windows For Rv Orange, CA

Rv Sofas Orange, CA

Rv Dinette Table Orange, CA

Rv Upholstery Orange, CA

Rv Replacement Awnings Orange, CA

Rv Carpet Installation Orange, CA

Rv Replacement Awnings Orange, CA

Rv Chairs Orange, CA

Awning Installation Orange, CA

Rv Restoration Companies Orange, CA

Replacement Rv Refrigerator Orange, CA

Replacement Windows For Campers Orange, CA

Rv Refrigerator Replacement Orange, CA

Rv Dining Table Orange, CA

Replacement Rv Windows Orange, CA

Replace Rv Flooring Orange, CA

Rv Replacement Awnings Orange, CA

Rv Replacement Furniture Orange, CA

Rv Restoration Companies Orange, CA

Rv Replacement Awnings Orange, CA

Rv Couch Orange, CA

Rv Dinette Booth Orange, CA

Rv Dining Table Orange, CA

Awnings For Trailers Orange, CA

Awnings For Trailers Orange, CA

Awnings For Trailers Orange, CA

Rv Interior Remodel Orange, CA

Rv Sofa Beds Orange, CA

Rv Chairs Orange, CA

Rv Carpet Replacement Orange, CA

Rv Interior Remodel Orange, CA

Rv Refrigerator Replacement Orange, CA

Rv Upholstery Orange, CA

Rv Dinette Table Orange, CA

Rv Dining Table Orange, CA

Awnings For Rv Orange, CA

Rv Carpet Installation Orange, CA

Rv Replacement Furniture Orange, CA

Rv Carpet Replacement Orange, CA

Rv Upholstery Orange, CA

Replacement Windows For Rv Orange, CA

Awnings For Trailers Orange, CA

Replace Rv Flooring Orange, CA

Rv Dinette Booth Orange, CA

Motorhome Carpets Orange, CA

Rv Sofa Beds Orange, CA

Rv Carpet Replacement Orange, CA

Replacement Rv Refrigerator Orange, CA

Remodeling Rv Orange, CA

Rv Chairs Orange, CA

Rv Floor Replacement Orange, CA

Replacement Windows For Rv Orange, CA

Replacement Windows For Campers Orange, CA

Replacement Rv Refrigerator Orange, CA

Replace Rv Flooring Orange, CA

Replace Rv Flooring Orange, CA

Replacement Windows For Rv Orange, CA

Rv Replacement Furniture Orange, CA

Rv Restoration Companies Orange, CA

Replace Rv Flooring Orange, CA

Close To Me Top Seo Company Orange, CA

Find Seo Company Orange, CA

OCRV Center

Table of Contents

- – Rv Dining Table Orange, CA

- – OCRV Center

- – Replacement Rv Refrigerator Orange, CA

- – Rv Sofas Orange, CA

- – Rv Interior Furniture Orange, CA

- – Replacement Rv Windows Orange, CA

- – Awnings For Rv Orange, CA

- – Rv Sofa Beds Orange, CA

- – Replace Rv Flooring Orange, CA

- – Rv Replacement Furniture Orange, CA

- – Rv Couch Bed Orange, CA

- – Awnings For Rv Orange, CA

- – OCRV Center

Latest Posts

Tankless Water Heater Installation Del Mar Heights

Tankless Hot Water Heater Installers Near Me Rancho Penasquitos

Plumber Near Me Clogged Toilet Tierrasanta San Diego

More

Latest Posts

Tankless Water Heater Installation Del Mar Heights

Tankless Hot Water Heater Installers Near Me Rancho Penasquitos

Plumber Near Me Clogged Toilet Tierrasanta San Diego