All Categories

Featured

Table of Contents

- – Rv Dinette Booth West Covina, CA

- – OCRV Center

- – Rv Couch Bed West Covina, CA

- – Rv Dinette Table West Covina, CA

- – Rv Replacement Furniture West Covina, CA

- – Rv Dining Table West Covina, CA

- – Rv Replacement Furniture West Covina, CA

- – Rv Refrigerator Replacement West Covina, CA

- – Awnings For Trailers West Covina, CA

- – Rv Replacement Awnings West Covina, CA

- – Rv Restoration Companies West Covina, CA

- – Rv Floor Replacement West Covina, CA

- – Rv Replacement Furniture West Covina, CA

- – Rv Interior Furniture West Covina, CA

- – OCRV Center

Rv Dinette Booth West Covina, CA

Various other terms for this type of window seal can be glazing or window trim. Example of fixed home window After you've confirmed your home window type, now it's time to locate the replacement seal.

This "picture" is a really crucial item to the problem. The 2nd piece of the puzzle is recognizing the dimensions of your profile (see what areas you require to measure with the example images below). In addition, you'll need to have an approximate footage in mind so you recognize just how much to purchase.

When you're shopping online, bear in mind that some manufacturers just offer their seals at a minimum or pre-cut lengths. That won't help every project. Ensure that the manufacturer you acquire from offers by the foot choices so you have control of rate and size. Scraper/Tuck Tool a fantastic device for eliminating the old seal, and pushing the brand-new seal in position Loctite Super Bonder 495 not required, yet will certainly add safety in corners if you need to make any adjustments Adhesive Cleaner the recreational vehicle manufacturer may have used adhesive to use the original seal.

These chemicals can be dangerous otherwise utilized right If you do not have every little thing on this listing, we've obtained you covered! See our Devices & Adhesive section. Some may be available at your local automotive parts store. Beginning by (very carefully) eliminating the home window. Place the window on a sheet covered table to stop scraping.

Rv Couch Bed West Covina, CA

Sticky eliminator is particularly handy here. It will strip everything off the window framework consisting of any type of adhesive that might have been Clean the motor home structure, or network where the home window rests. You will desire a tidy surface for your brand-new seal When every little thing is tidy, take your new seal and press right into location.

Gaskets will certainly make an audible audio when they have actually broken right into area. Something else to note: some setups may need you to get rid of the glass from the window framework.

Rv Dinette Table West Covina, CA

After the glass is removed, the seal installment must be the same as outlined over. Steele not just supplies premium items, yet additionally the knowledge to assist you complete your tasks. If you have questions pertaining to weatherstripping for your traditional lorry, road pole, RECREATIONAL VEHICLE, or boat, don't be reluctant to call us! Call us at 800-447-0849, send us an email, or chat with us on our website.

Recreational vehicle home window substitute is one of the easiest do-it-yourself tasks. All you do is eliminate a couple of screws, stand out the old home window out, use sealant, and stand out the new window in. Obviously there are a couple of additional actions, which we'll reach momentarily, but that's the fundamental treatment.

You can go with a different window kind if you such as. If you want far better insulation from the warm and the cold, you can update from solitary pane to increase pane home windows.

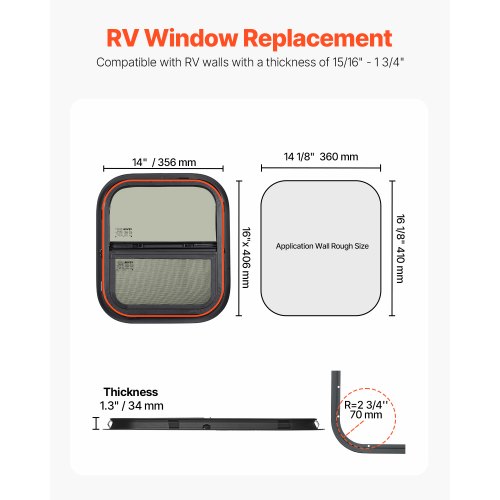

Accurately measuring the measurements of your old home window, or your home window opening, is important when ordering replacements. Repaired pane/awning home window combination by Kinro The majority of Motor home home windows are clamp ring placed.

Rv Replacement Furniture West Covina, CA

Stress holds the window in position. Placing screws are on the within of the window, leaving a smooth appearance on the exterior. Replacement motor home windows normally come packaged with indoor trim rings, screws, and putty tape, so no additional hardware is required. One individual can change a window, though it will certainly be bit easier with two people, specifically if it's a large window.

If you're replacing all the windows on your camper, you'll most likely shave off some of that time after doing a couple. Philips Screwdriver Putty Blade, Scrape Tool, or Flat Head Screwdriver Silicone Sealant Spray Container of Water Leader or Tape Step Tape, if no helper is offered (blue painter's tape works best) The first 3 steps include removing the old window and sealant From inside the Recreational vehicle, begin by removing the drapes and blinds.

Rv Dining Table West Covina, CA

Now you'll eliminate the screws from the inside window trim ring. Prior to getting rid of the last few screws, you'll require a helper to hold up the window on the outside to avoid it from falling to the ground.

Even more than likely, the window will still be held in location by caulking and putty tape. Currently you'll relocate outside the RV, and with a putty knife under the exterior window flange, carefully tear the home window out from the sidewall. It helps to have another individual keep the window while you tear it out.

A tidy surface will certainly give a far better hold for the brand-new putty tape and caulking, and make a much better seal. Currently it's time to appear that shiny brand-new motor home home window and seal the deal Dry fit the brand-new RV home window initially, to make sure it fits appropriately. Do this by positioning the home window in the opening, without any type of putty tape.

Rv Replacement Furniture West Covina, CA

If there is less overlap on top, you'll need to use shims to increase the window up from the base. The window ought to be centered in the window opening, both up and down and horizontally.

Use the supplied putty tape to the RV sidewall around the boundary of the home window opening. You do not desire any kind of voids for water to sneak in between the exterior home window flange and the RV sidewall.

This will certainly prevent the home window from sticking to the putty tape, providing you some time to center the home window. Now set up the window, focusing it in the home window opening.

As soon as the screws are tightened, go outside and examine that there are no gaps in the putty tape. Apply much more putty tape if necessary. Cut off any type of excess putty tape. For added insurance coverage against water damage, apply a bead of clear silicone sealer around the window frame. Smooth out the sealer with a flat head screwdriver or finger moistened with your spray bottle.

Rv Refrigerator Replacement West Covina, CA

A RV is component house and component car, and often, after the "house" has actually been driven for miles and miles over rough roads, maintenance concerns can occur. Amongst the possible fixings that a motor home owner might encounter is a recreational vehicle window substitute. We faced this problem a number of years back and satisfied it head-on with our wish to DIO (Do It Ourselves) as a lot of our own RV repair and maintenance jobs as feasible.

For those of you that are much more aesthetic, you'll appreciate our detailed guide video clip, ingrained listed below. If you like the created word, the actions are laid better down the web page. Or enjoy both! These are the devices we required for our camper window substitute. Depending upon your motor home, you might or may not require all of these tools for your job.

Despite where you get your brand-new RV window, you'll require to offer exact dimensions. Allow's break down our procedure for determining a recreational vehicle window for replacement. Begin by getting rid of any type of home window frame, blinds, or tones. Next off, remove all screws around the boundary of the window, and get rid of the inside frame.

Awnings For Trailers West Covina, CA

Do not put any kind of outward stress on the home window while taking your measurements or it might come loose and fall. For added safety and security, you may intend to have a helper on a ladder outside, holding the home window in position while you gauge. Thoroughly remove the structure of your old home window to make sure that you can determine the opening (NOT the window itself).

For our rectangle-shaped home window, we needed to take just 4 dimensions. Please keep in mind that we're gauging the opening itself. Utilizing a measuring tape, take cautious note of the width and elevation of the opening. It's a great idea to take dimensions at a number of points so you have an idea of just how easily the home window opening was cut.

Rv Replacement Awnings West Covina, CA

Dimensions of the old home window and the window opening are typically various. As a matter of fact, they can differ as much as half an inch on the sides, top, and base. Home window makers utilize filler strips to maintain the home window level and snug. This is why it's so essential to determine the opening and not the original window itself.

Step twice, cut once? Take your time to get a precise dimension, and confirm it by gauging a second time. Exact dimensions are very important to RV window substitute. We do not intend to freely determine and assemble or down. Constantly measure to the nearby 1/16th of an inch. Take a close consider your measuring tape and make certain you understand which are the 1/16th-inch dimensions.

Rv Restoration Companies West Covina, CA

The window producers are the finest authorities on mounting their items. Rv Dinette Table West Covina. The manufacturer of your brand-new RV window has likely included practical standards or suggestions to make the installment simpler.

There might be a grain of sealer around the top of your old home window or between the external home window structure and the motor home's sidewall. If so, you'll require to remove this prior to eliminating the old home window. Transferring to the beyond the RV, utilize your plastic putty blade (yes PLASTIC, to stay clear of damaging your recreational vehicle's coating) to carefully break the seal around the old window and eliminate it.

Rv Floor Replacement West Covina, CA

Make sure the home window is OPEN so that you can strongly understand the home window as it falls out of the opening, as soon as the seal is damaged. Scrape off any kind of continuing to be sealer using your plastic putty blade, and clean up off any kind of continuing to be particles making use of mineral spirits. Provide the location a last cleansing making use of rubbing alcohol to make certain that the area around the home window opening is free of any kind of oily residue.

Begin by establishing your brand-new window on a level surface covered with a soft towel, with the beyond the home window encountering down. Tidy right around the side with massaging alcohol and a tidy fabric. This will certainly guarantee that the surface is free from all residue. Making use of the included roll of double-sided, closed-cell foam tape, apply the tape.

Rv Replacement Furniture West Covina, CA

Measurements of the old home window and the home window opening are frequently various. As a matter of fact, they can vary as long as half an inch on the sides, leading, and base. Home window suppliers make use of filler strips to keep the home window level and snug. This is why it's so important to determine the opening and not the original window itself.

Take your time to get an exact dimension, and ascertain it by determining a second time. Specific dimensions are important to Recreational vehicle window substitute. Take a close look at your tape step and be certain you know which are the 1/16th-inch dimensions.

The window makers are the finest authorities on installing their products - Rv Dinette Table West Covina. The maker of your brand-new Recreational vehicle home window has most likely included practical guidelines or pointers to make the setup less complicated.

Rv Interior Furniture West Covina, CA

There may be a bead of sealant around the top of your old home window or between the outer window structure and the recreational vehicle's sidewall. If so, you'll require to eliminate this previous to removing the old home window. Transferring to the outside of the recreational vehicle, use your plastic putty knife (yes PLASTIC, to avoid scratching your recreational vehicle's surface) to carefully break the seal around the old home window and remove it.

Make sure the window is OPEN so that you can firmly comprehend the window as it befalls of the opening, as soon as the seal is broken. Scratch off any kind of remaining sealer utilizing your plastic putty blade, and cleanse off any kind of staying particles making use of mineral spirits. Give the area a last cleaning making use of rubbing alcohol to make sure that the area around the home window opening is without any oily residue.

OCRV Center

Address: 23281 La Palma Ave Yorba Linda, CA 92887Phone: (714) 909-1444

Email: [email protected]

OCRV Center

Begin by setting your brand-new window on a flat surface covered with a soft cloth, with the exterior of the home window encountering down. Clean right around the edge with rubbing alcohol and a clean cloth. This will guarantee that the surface area is clear of all residue. Using the included roll of double-sided, closed-cell foam tape, apply the tape.

Rv Carpet Replacement West Covina, CAReplace Rv Flooring West Covina, CA

Rv Interior Furniture West Covina, CA

Rv Chairs West Covina, CA

Rv Refrigerator Replacement West Covina, CA

Replacement Windows For Rv West Covina, CA

Rv Interior Furniture West Covina, CA

Rv Couch West Covina, CA

Rv Refrigerator Replacement West Covina, CA

Rv Sofa Beds West Covina, CA

Rv Dining Table West Covina, CA

Rv Interior Furniture West Covina, CA

Rv Refrigerator Replacement West Covina, CA

Rv Refrigerator Replacement West Covina, CA

Rv Microwave Replacement West Covina, CA

Rv Interior Remodel West Covina, CA

Rv Sofa Beds West Covina, CA

Rv Replacement Furniture West Covina, CA

Rv Floor Replacement West Covina, CA

Rv Chairs West Covina, CA

Replacement Rv Windows West Covina, CA

Rv Sofa Sleeper West Covina, CA

Rv Replacement Awnings West Covina, CA

Rv Sofas West Covina, CA

Rv Replacement Furniture West Covina, CA

Rv Restoration Companies West Covina, CA

Replacement Windows For Rv West Covina, CA

Replacement Windows For Rv West Covina, CA

Rv Dining Table West Covina, CA

Replacement Windows For Rv West Covina, CA

Rv Couch West Covina, CA

Rv Restoration Companies West Covina, CA

Rv Sofa Sleeper West Covina, CA

Rv Sofa Beds West Covina, CA

Replacement Windows For Campers West Covina, CA

Replacement Windows For Campers West Covina, CA

Rv Replacement Furniture West Covina, CA

Awning Installation West Covina, CA

Replacement Rv Refrigerator West Covina, CA

Replacement Rv Windows West Covina, CA

Awnings For Trailers West Covina, CA

Rv Dinette Table West Covina, CA

Rv Chairs West Covina, CA

Rv Refrigerator Replacement West Covina, CA

Replacement Rv Refrigerator West Covina, CA

Rv Replacement Awnings West Covina, CA

Replacement Windows For Campers West Covina, CA

Replacement Windows For Campers West Covina, CA

Rv Sofa Beds West Covina, CA

Rv Couch West Covina, CA

Remodeling Rv West Covina, CA

Rv Refrigerator Replacement West Covina, CA

Replacement Windows For Campers West Covina, CA

Remodeling Rv West Covina, CA

Awnings For Rv West Covina, CA

Rv Chairs West Covina, CA

Rv Dinette Table West Covina, CA

Replacement Windows For Rv West Covina, CA

Awning Installation West Covina, CA

Rv Refrigerator Replacement West Covina, CA

Rv Upholstery West Covina, CA

Awning Installation West Covina, CA

Replacement Rv Refrigerator West Covina, CA

Replacement Rv Windows West Covina, CA

Rv Dinette Booth West Covina, CA

Replacement Rv Windows West Covina, CA

Rv Microwave Replacement West Covina, CA

Rv Microwave Replacement West Covina, CA

Rv Microwave Replacement West Covina, CA

Rv Sofas West Covina, CA

Rv Sofa Beds West Covina, CA

Motorhome Carpets West Covina, CA

Rv Upholstery West Covina, CA

Rv Sofas West Covina, CA

Awnings For Trailers West Covina, CA

Remodeling Rv West Covina, CA

Awning Installation West Covina, CA

Rv Sofa Sleeper West Covina, CA

Near Me Seo Company Near Me West Covina, CA

Near Here Seo Companies West Covina, CA

OCRV Center

Table of Contents

- – Rv Dinette Booth West Covina, CA

- – OCRV Center

- – Rv Couch Bed West Covina, CA

- – Rv Dinette Table West Covina, CA

- – Rv Replacement Furniture West Covina, CA

- – Rv Dining Table West Covina, CA

- – Rv Replacement Furniture West Covina, CA

- – Rv Refrigerator Replacement West Covina, CA

- – Awnings For Trailers West Covina, CA

- – Rv Replacement Awnings West Covina, CA

- – Rv Restoration Companies West Covina, CA

- – Rv Floor Replacement West Covina, CA

- – Rv Replacement Furniture West Covina, CA

- – Rv Interior Furniture West Covina, CA

- – OCRV Center

Latest Posts

Marketing Internet Marketing Walnut

Riverside Internet Marketing

Internet Marketing Corona

More

Latest Posts

Marketing Internet Marketing Walnut

Riverside Internet Marketing

Internet Marketing Corona